4.5 Commissioning for LevelLink

Level

When an iFUEL Mobile unit is installed with a level gauge, this guide must be followed at time of commissioning.

4.5.1 Stages of Level CommissioningLink

- Installation of componenets

- Preparation of strapping table and measurements

- Activation of system

- Onsite calibration, testing and adjustments

4.5.2 InstallationLink

The level probe must be installated above the tank floor. Where a tank may become contaiminated with water, algae or dirt the iFUEL Level probe will fail.

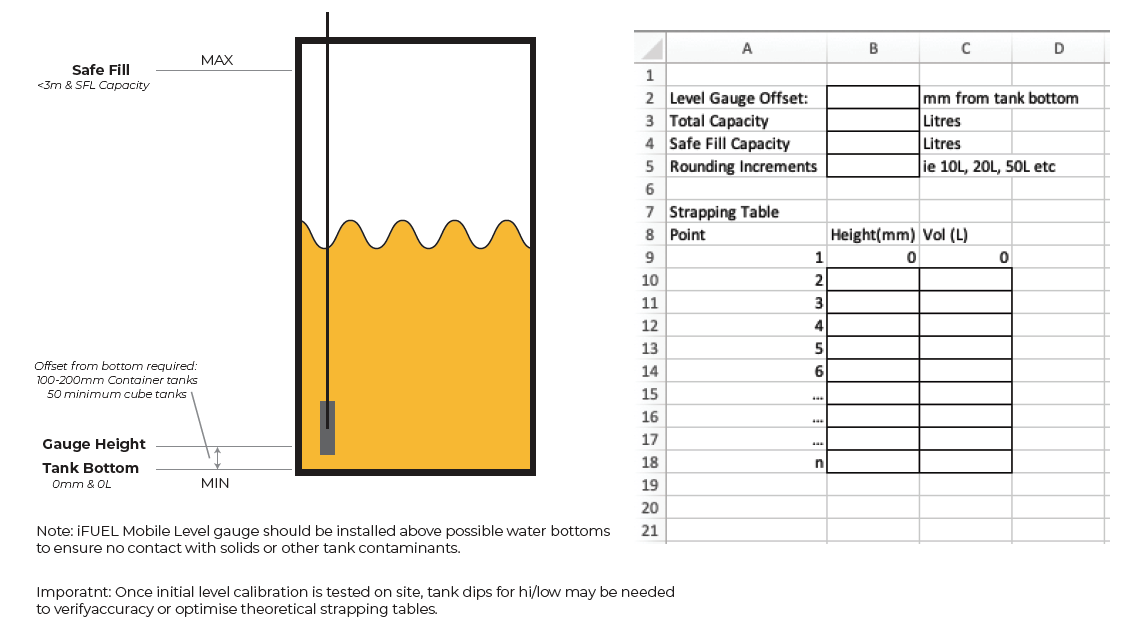

For cube tanks install the Level Probe approx 50mm above the tank floor. For container tanks install the Level Probes 100mm above the tank floor

The Level Probe must be secured to a physical part of the tank and not left floating.

Take careful note of the height of the installed probe as thi will be needed later

4.5.3 Preparation of strapping table and measurementsLink

To create the strapping table the detailed tank height vs volume data is needed. Where this is not available, measurements from the dip stick are needed. In the very worst of cases a theoretical volume vs height can be used.

An example of the measurements and data needed are shown here.

Submit the data to your iFUEL Mobile contact. 24-48 hrs are needed to get the data into the iFUEL system.

On occasion we may increase the Rounding Increments to ensure performance inline with the systems accuracy.

4.5.4 System ActivationLink

Once the data has been submitted, the Level features will be enabled for this iFUEL device.

- Prepare and import the strapping table

- Modify the iFUEL Mobile devices system registration

Site commissioning or system testing must not commence until this stage is complete.

Don't forget to modify the SD Card contents of the iFUEL Mobile to ensure the level feature is enabled.

1 2 3 4 | #! /sdCardContents/flx.ini ... Level_Instrument=1 ... |

4.5.5 Onsite calibrationLink

Once onsite and the tank is ready for first fuel, have the delivery operator fill the tank to just over the system suction point and the level probe.

Where possible do a small iFUEL Mobile fuel dispense. Be sure the note the date/time volume recorded and the Dip Stick Level and keep this information close to hand.

When the fill is complete repeat the procedure. This creates a Low/Hi points to check that can be confirmed against actual data.

If the Strapping Table needs to be corrected this data is required.

Keep in mind if this step can't be conducted at commissioing the customer will need to verify the reliability of the level probe and collect new data points

4.5.6 Notes on LevelLink

The Level Gauge shall not be used to audit the dispensing meter. The Level Gauge has no where near the accuracy and precision of the meter. Meters can measure in fractions of a Litre, where the Level Gauge can only measure in hudreds (or thousands) of Litres at best.

Warning

The purpose of the Level System is to all scheduling only.

Please be sure the customer understands the principle of the Level System is to schedule deliveries to the tank.4.5.7 Ongoing CalibrationsLink

From time to time the level probe may appear to be innacurate or need recalibration.

Once the level gauge is active we can use Transactional data (and sensor readings) and just need dip stick data with multiple readings to recreate the Strapping Table.

4.5.8 Deviation from TheoreticalLink

When tanks have any of the following features:

- Non perfect level

- Dents and imperfect sides

- Bowed panels

- Bullet ends

- Minor twists and warps

- Curved bottoms

- Sloping bases

The theoretical strapping table approach may b inadequte to create a reliable calculation. Under these circumstances multiple dip/sensor readings will be needed to optimise the ability of iFUEL Mobile to caluclate tank levels.